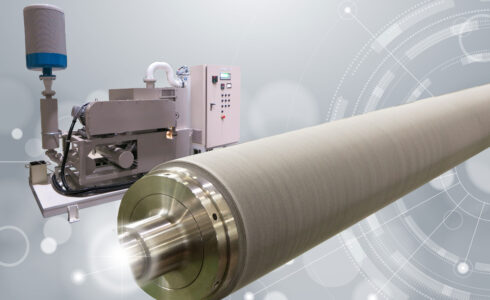

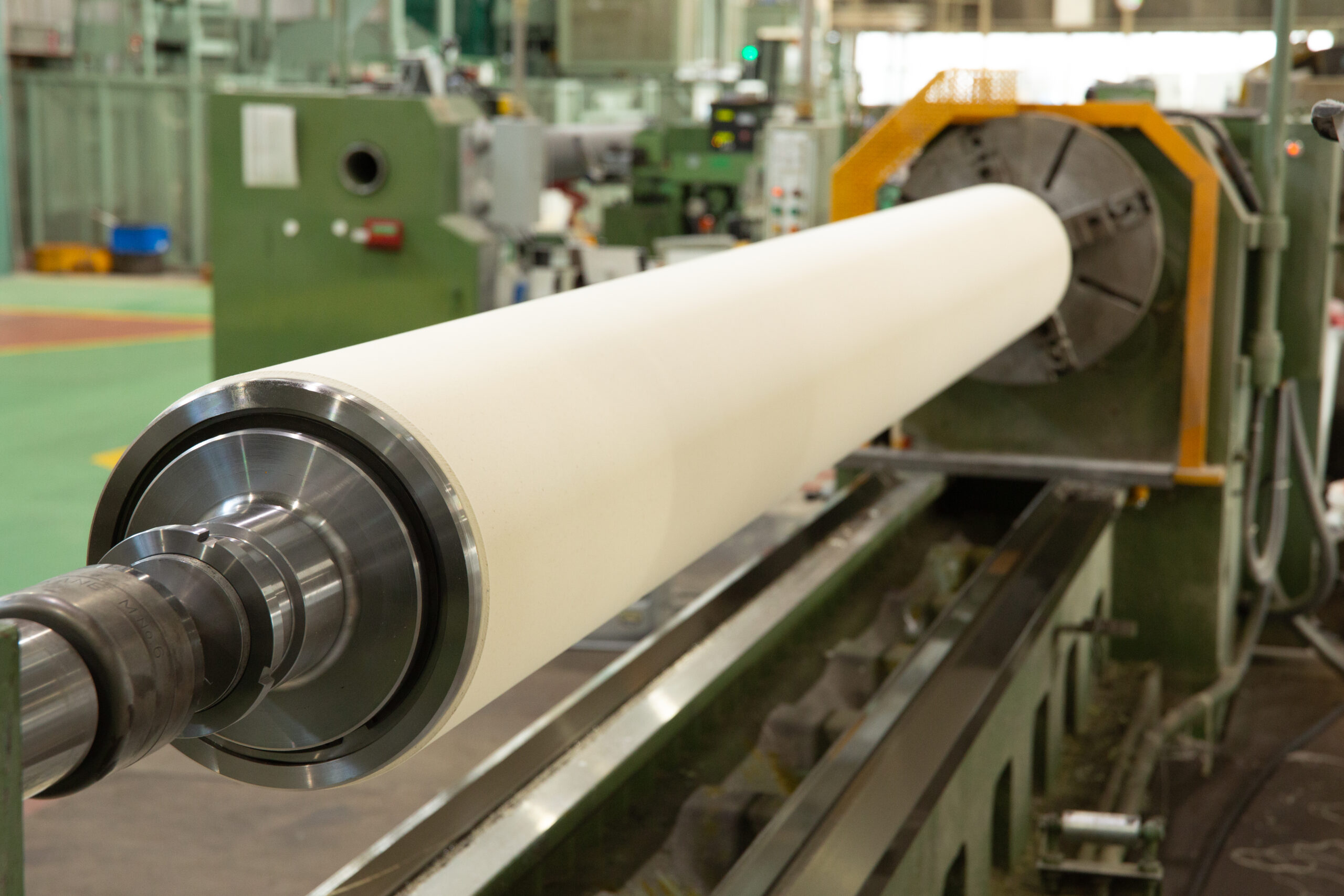

66D NON-TEX ROLL

66D NON-TEX ROLL is a nonwoven fabric stacked in layers and compressed on a shaft. Different materials and compositions enable to design rolls to meet various applications.

FEATURES

- High Coefficient of Friction

No slippage on the surface of rotating rolls. - High Squeezing Performance

Squeezing and damming water, oil and others. - High Edge Resistance

High elasticity and high abrasion resistance. - Damages and scratches on the roll are not marked on the products

Protecting and preventing from marking on the products. - Variety of applications

Selectable variety of nonwoven materials, compositions and

hardness enable to apply for water, oil and chemical solutions.

66D NON-TEX ROLL’s Characteristic 1

By effects of damming and *continuous absorbing/exhausting*,

squeezing performance is better than rubber rolls.

*Nonwoven fabrics, in a sponge-like porous structure with innumerable apertures, enable continuous absorbing and exhausting liquid. When the roll is released from the plate, liquid on the plate is absorbed into the roll. When the roll is pressed on the plate, liquid absorbed into the roll is exhausted*

66D NON-TEX ROLL’s Characteristic 2

Slipping marks hardly occur on the material (plate, sheet and etc.) passing through under the roll.

Hydroplaning phenomenon and slipping hardly occur, because the porous structure absorbs liquid and air on the materials.

66D NON-TEX ROLL’s Characteristic 3

Foreign matters are remained on the roll surface, and damage on the material passing through the roll.

RUBBER ROLL

Foreign matters are taken into the roll consisted of nonwoven fabric in porous structure. Damages hardly occur on the material passing through the roll.

66D NON-TEX ROLL

66D NON-TEX ROLL’s Characteristic 4

Rubber roll is easy to be scraped or peeled off by edges of the material, and unable to restore.

RUBBER ROLL

66D NON-TEX ROLL has high durability against external stress, and self-resilience.

66D NON-TEX ROLL

APPLICATIONS

General

No slippage. Squeezing rolls, Oiling rolls, Control rolls, and others

Steel and Non-Ferrous Metal Industries

- Wringer rolls for oil, water and chemical solutions.

- Oiling rolls

- Control rolls(Tension, Pinch, Feed, Table, Guide and others)

Automotive Industries(Car body production lines)

- Wringer rolls, Oil cut rolls

- Wiper rolls and Pinch rolls

Film, Sheet and Textile Industries

Wringer rolls, Wiper rolls and Control rolls(Tension, Pinch, Feed,

Table, Guide and others)

Main Materials and Characteristics

| Material | Applications | Characteristics |

|---|---|---|

| OW-90H | Wringer roll | Oil proof, high abration resistance |

| PC-67 | Wringer roll, oiling roll |

Oil proof, High squeezing performance from starting to use |

| PC-97 | Wringer roll | High abration resistance, oil/water/weak-Alkali solution |

| OR-210 | Oiling roll | High oil retention |

| CR-83 | Control roll | High pressure and abration resistance |

| CR-87 | Control roll | Acid/solvent resistance |

| OHP-74 | Wringer roll | Acid/Alkali resistance |

| OHN-74 | Wringer rol | Alkali resistance |

※Contact us for more information. We can select an appropriate nonwoven material for your application

Available Range of Roll Size