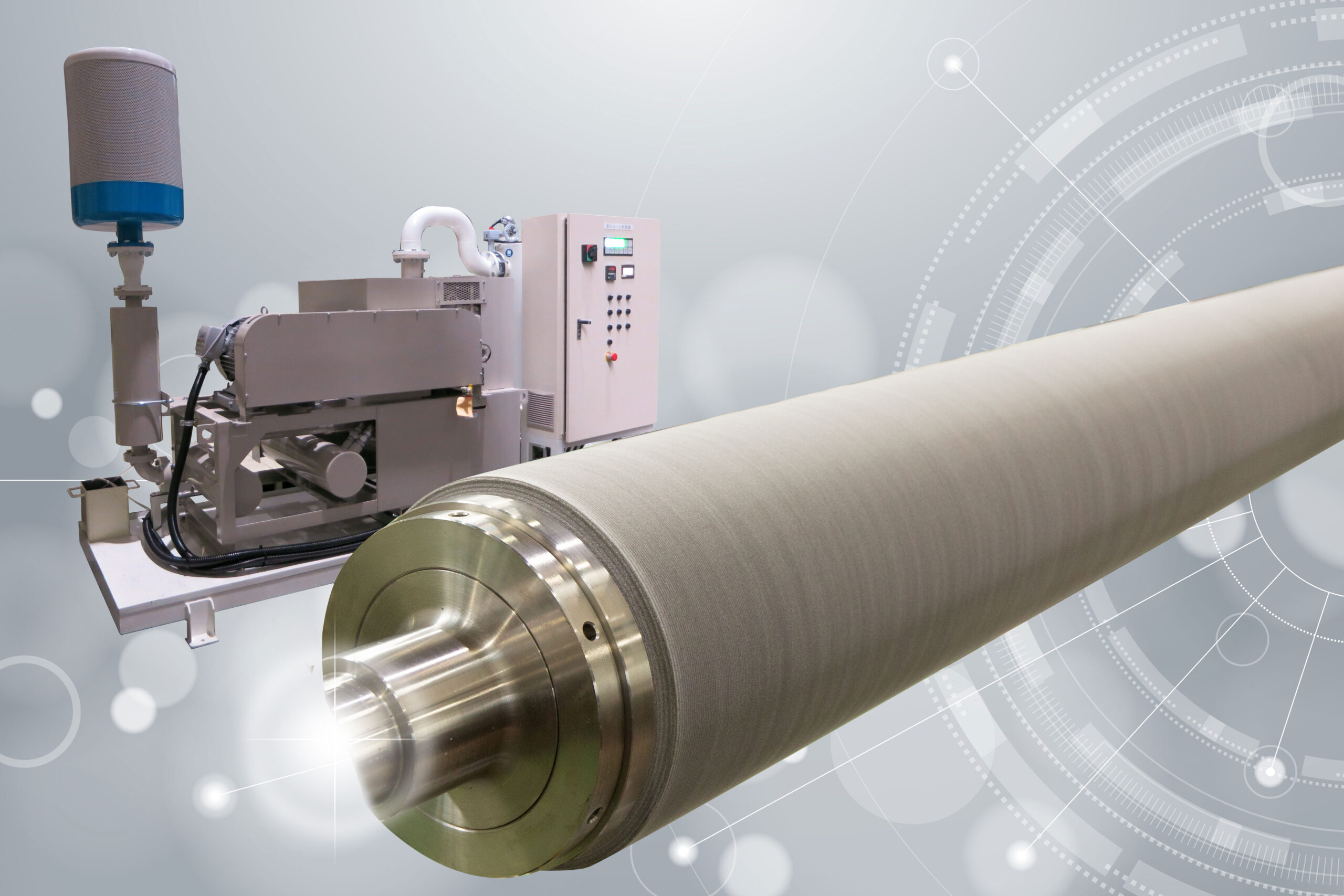

VACUUM ROLL・VACUUM EQUIPMENT

Vacuum roll is a nonwoven roll reinforced sucking and washing oil, water and other solutions by combination with a vacuum equipment.

FEATURES

- Speed-Up Production Line

Capillary phenomenon effected by nonwoven fabric and reinforced suction by a vacuum equipment enable to decrease quantity of excess oil and speed up the production line. - Improving Cleaning Power

By drastically decreasing excess oil, quantity of washing oil can be increased to improve cleaning power furthermore. - Adjustable Quantity of Excess Oil on the plate

Controlling the vacuum equipment by the inverter enable to adjust vacuuming power, and control quantity of excess oil on the plate.

APPLICATIONS

General

Steel and Non-Ferrous Metal Industries

Wringer rolls for ECL(Electrolytic Cleaning Line)and CAL(Continuous Annealing Line).

Oil cut rolls for leveler and re-coiler

Automotive Industries(Car body production line)

Wringer rolls in washing machine on the press line

TOHO Vacuum Roll System Unit for Automotive Industries

TOHO Vacuum Roll System Unit in the Washing Machine

TOHO Vacuum Roll System Unit

By select and set oil film thickness desired,

the OIL FILM THICKNESS is formed on the blank plate with following flow

(JAPAN PATENT NO.6340603)

*PID (Proportional Integral Derivative) is a control loop mechanism employing feedback that is widely used in industrial control systems.

*Its protocol are FL-net・CC-Link・Device Net・etc

TOHO Vacuum Roll System Unit adopts AIR COOLING VACUUM PUMP

NO water, chiller, plumbing pipes

NO those related operating and maintenance works

Conventional Vacuum Roll System Unit

*Enough spaces to install a chiller and plumbing pipes are necessary.

*To avoid rust caused by cooling water, regular cleaning works for pump, chiller and plumbing pipes are required.

TOHO Vacuum Roll System Unit

*To keep well-performance of the vacuum rolls, regular dressing (grinding roll surface) is recommended.

Increasing

Productivity

Speeding up production

Decreasing defective ratio

Decreasing manpower

Saving oil, water and electricity

Operation

Maintenance

Works